Roll-to-roll flexible perovskite solar cells hit record efficiency

March 10, 2017 // By Nick Flaherty

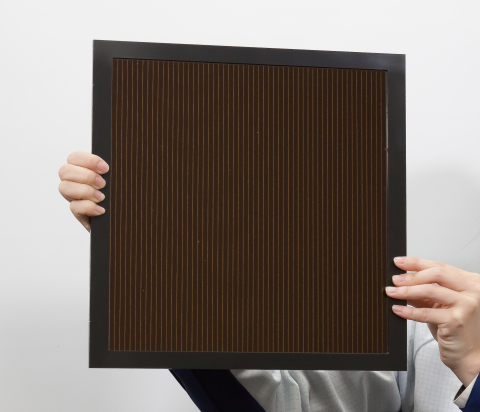

A pan-European collaboration has achieved a record efficiency of 12.6% for roll-to-roll flexible solar cells using perovskite materials.

A pan-European collaboration has achieved a record efficiency of 12.6% for roll-to-roll flexible solar cells using perovskite materials.

Solliance, a grouping of research centres and companies from Holland, Belgium and Germany with Solartek, Dyesol and Panasonic, has used an industrially-applicable roll-to-roll process for the production of these cells, paving the way to an accelerated market introduction.

Perovskite microcrystals are a promising material to make high-yielding, thin-film solar cells. They can be processed into thin, light-weight and potentially semitransparent modules that could eventually be integrated in building materials such as windows or curved construction elements. Solliance and its research partners focus on using scalable, industrial processes towards the fabrication of large-area modules, eventually suitable for seamless integration in a broad variety of PV systems.

The current world record efficiency of a small, lab scale perovskite-based PV cell is 22.1%, while other roll to roll technologies using organic dyes have reached 13%.

“The challenge is to upscale perovskite cells to larger size, industrially-manufacturable modules with high efficiency and long lifetime at low cost," said Ronn Andriessen, Program Director at Solliance. "These 12.6% R2R up-scaled perovskite-based solar cells are a first and important step in this development. With this result, we are confident to quickly boost the up- scaled perovskite based PV module efficiency above 15% by using low cost materials and processes. Furthermore, we are working hard to improve the stability of these devices under real life operational conditions."

The roll-to-roll (R2R) process was developed for both the electron transport and the perovskite layers on the new Solliance dual R2R coating line, as developed by Solliance with its partners VDL Enabling Technologies Group (VDL ETG), Smit Thermal Solutions and Bosch-Rexroth. The in-line roll-to-roll coating, drying and annealing processes were executed at a linear speed of 5 m/min on a 30-cm wide commercial PET/ITO foil and under ambient conditions. After applying a newly developed off-line single device finishing step, individual solar cells of 0.1cm2 achieved efficiencies of up to 12,6%, measured under maximum power point tracking conditions during 5 minutes. All process steps on this roll-to-roll line were performed using low cost materials whilst keeping the process temperatures below 120 °C. This shows the high volume production potential of this new emerging thin film PV technology.